3D printing might still change everything

I wrote in a recent post about how predicting what will happen is easy, but predicting when it will happen is hard. Here's a very personal example: I thought the 3D printing revolution would be much further along by now. I even said as much on national radio, on new years day in about 2016, from memory.What I mean by the 3D printing revolution is a fundamental change in the way we produce and buy physical goods. Everything from clothes to cutlery, to consumer electronics. Right now, most of our goods are produced in giant factories, or networks of smaller ones, on the other side of the world where labour is cheap, or raw materials are accessible. They are then shipped or flown to us to trickle down through a network of distributors, wholesalers, brands and retailers, before landing in our homes or on our person.The possibility with a new range of manufacturing technologies is that instead of shipping finished products we ship a smaller range of base materials that can be transformed into products by machines driven by digital patterns. At home or in local bureau, the raw materials are transformed into the goods we want. The potential advantages? Lower environmental costs, reduced waste, total personalisation, easier recycling. With the right technologies in place, and the accompanying shift in economic power and consumer culture, we could see a very, very different - and arguably better - world.I didn't think we would be there now. But I thought we would have taken the first step. I thought basic 3D printers would have become more reliable, and cheaper, so that they were as common as inkjet printers in your average family home in the late 90s/early 00s. This hasn't happened.The price has fallen, for sure. You can now get a basic 3d printer for around £100, and a good one like my own Creality CR10S Pro for around £500. But 'good' for 3D printers remains a relative term. They still require a lot of fettling to print reliably. The process for turning out goods is nowhere near as accessible as say, desktop printing, even though great strides have been made with incredible software like TinkerCAD, Fusion360 and Cura. The finish on these goods is often still rather rough. The 3D printer is still not a mass market machine, as evidenced by the curiosity that is engendered in people when I tell them the noise they can hear in the background of our conference call is something printing.And yet, the potential is still there. And my enthusiasm for it has been renewed by a recent side project.

Keeping your data on site

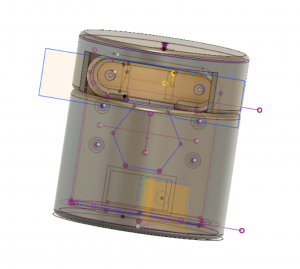

The world of home automation enthusiasts is up in arms at the moment because many of the big software and hardware companies involved keep changing the rights of developers to connect in to their home automation devices. Application Programming Interfaces (APIs), the means by which one piece of software can talk to another, are getting turned off and breaking what might be years of hard work from the open source community. At the same time, these companies are often selling services that rely on our personal data being stored on their servers, sometimes with them having rights to use that data for targeted advertising or other analysis.In a recent example, Google announced it would be turning off the Works with Nest programme by which my thermostat talks to the rest of my home. From August, I will no longer be able to automatically turn the heating down when the alarm is armed, or control it from the same panels from which I control the rest of my home*. This is a problem only for those at the intersection of privilege and geekery, but it has offended many.The result is that more and more enthusiasts are turning away from any product that relies on cloud-based software beyond their control, and looking for alternatives. There are many great software alternatives, like the incredible Home Assistant project. But there are fewer options in hardware. So having refreshed my 3D design skills (I originally studied Mechatronic Engineering), I set about starting to design some. The first project has been a network connected camera to replace the ones in my cloud-based alarm system. These are different from your average camera because they have a physical privacy shield that slides into place when the alarm isn't armed, removing that sense of being watched in your own home. I wanted to replicate this, so designed a camera with a rotating shield driven by a small servo. The whole thing is powered by a Raspberry Pi and should be assembled for under £50 if you have the requisite skills. It's still a work in progress but when it's a little more polished I'll move all the code and design files to a shared repository so that it is updated as I make changes, and post a full build guide.

So having refreshed my 3D design skills (I originally studied Mechatronic Engineering), I set about starting to design some. The first project has been a network connected camera to replace the ones in my cloud-based alarm system. These are different from your average camera because they have a physical privacy shield that slides into place when the alarm isn't armed, removing that sense of being watched in your own home. I wanted to replicate this, so designed a camera with a rotating shield driven by a small servo. The whole thing is powered by a Raspberry Pi and should be assembled for under £50 if you have the requisite skills. It's still a work in progress but when it's a little more polished I'll move all the code and design files to a shared repository so that it is updated as I make changes, and post a full build guide.

3D printing: not just geeks

Right now my little creation is only of interest to geeks like me. But building it has shown me that while my expectations for 3D printing may have been optimistic, we're not that far off. It's very easy to see that in a few years, devices like this could roll off a 3D printer with all of the required wiring embedded, have a standard microprocessor added (it could be programmed on the same machine that builds the body), and you have an instant piece of custom consumer electronics. Since anyone can share a digital design at nearly no cost, the range of options could be nearly infinite. A ratings system could ensure that you only print things that work.This isn't a new idea but it's one that still excites me, and it's one that I can see being realised in some form in the future. Just not quite yet. *Google has since relented, allowing people like me to keep their developer accounts for the time being.